Harbor Freight Tools 219 User Manual - Page 8

Troubleshooting, Maintenance

|

View all Harbor Freight Tools 219 manuals

Add to My Manuals

Save this manual to your list of manuals |

Page 8 highlights

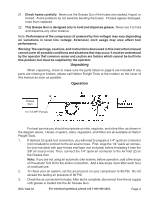

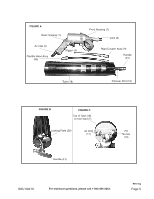

Troubleshooting If the Grease Gun does not operate: 1. Check that gun is properly connected to the air source and the air compressor is set to 30 - 100 PSI. 2. If it still doesn't operate, take it to an qualified service technician to check the Springs (6 and 17), and the Piston Assembly (5). If the Grease Gun cycles and does not pump grease: 1. Repeat priming operation on page 7. 2. Check to see if you are out of grease. 3. Disconnect any extensions and prime until grease flows. If the Grease Gun continues to lose prime: 1. Release trapped air. 2. Refill the Grease Gun and repeat priming. 3. Have an qualified service technician check the position on the Follower Assembly. If the Grease Gun still doesn't operate, contact a qualified service technician. Maintenance Always disconnect from the air source hose before attempting any maintenance. 1. After each use, clean leftover grease from the Tube (18). 2. Make sure the Nozzle (10) and the tip of the Grease Gun are clear of dirt, grease, or any debris. 3. Wipe down the unit with a lint free cloth. SKU 00219 For technical questions, please call 1-800-444-3353. REV 09b Page 8